RFID Tagging Explained

A clear guide to passive UHF RFID for better control of inventory and assets.

RFID Tagging Explained

A practical guide for better control of assets and inventory.

Barcodes had their moment. But scanning one box at a time doesn’t cut it when you’re dealing with pallets, surgical kits, or high-value tools. That’s where RFID steps in. With accuracy rates above 99% and the ability to read hundreds of items in seconds, RFID has become the backbone of modern asset tracking across retail, logistics, healthcare, construction, and manufacturing.

The right tag, in the right place, applied in the right way. Get that wrong and even the best system will stumble. Get it right and you’ll hit near-perfect accuracy. Inside you’ll find:

The basics

How RFID works and why passive UHF RFID tags are the sweet spot for range, speed, and affordability.

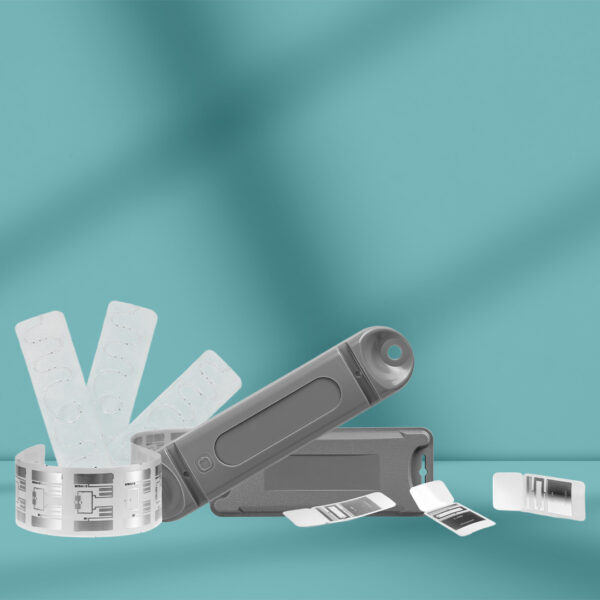

The anatomy of a tag

Chip, antenna, substrate, and how each part affects performance.

Different tag types

From labels and hard tags to on-metal tags and inlays, and where each one makes sense.

Placement tips

Do’s and don’ts that make the difference between reliable reads and frustrating blind spots.

How to get items tagged

Source tagging at manufacture, warehouse tagging on arrival, in-store tagging for exceptions. And why most businesses end up with a mix.

Hot and cold spots

Why RFID signals don’t always behave like you expect, and how to design around it.

If you’re starting an RFID project or just curious about how tags really work, this guide will give you the clarity you need before you order in bulk.

Download the guide and learn how to choose, apply, and trust your tags.

Discover the Power of RFID Technology with Ramp:

Ever wondered how RFID technology transforms the way we track assets and inventory? Dive into our latest video to learn more about RFID technology, its applications, and how it’s revolutionising asset and inventory management.